Why do my Dymo labelmaker labels keep falling off?

If your labels start peeling off then the most common issue is that either the surface wasn't clean when the label was applied, or the labels were just not suitable for the surface you are sticking them to. The environment can also cause problems (eg. vinyl labels don't like heat, polyester labels don't like curved surfaces, and nylon labels don't like water, oil or contact with solvents or cleaners etc).

A common mistake when purchasing a label maker is to just buy the cheapest labeller available and assume it will do the job. But often the cheapest printers come with the most basic labels, which may not be suitable for the surface(s) you want to label. This is especially true if you want to label not-flat and/or non-smooth surfaces.

In fact the better way is to identify what you want to label, then find out which are the best types of labels for that application, then find a label machine that can print those labels.

For example the Letratag range are low end consumer labels designed for smooth, clean, flat surfaces, while the Dymo D1 (Labelmanager) range is designed more for the office environment - but again they're still designed for smooth flat surfaces (though the D1 range does include a flexi nylon tape, and some specialist labels with stronger adhesive).

So if you try to attach these labels to curved surfaces it's likely they will come unstuck at some point. Many label materials actually resist curving (Nylon does not, making it ideal for curves) and therefore actively work against the adhesive, resulting in them eventually falling off. The same can happen if the surface is slightly textured or not completely clean when the label is applied.

So if you are planning to label rough, dirty, oily, curved or otherwise non-flat/smooth/clean surfaces - especially cables - then you should look for the best label to do the job, and then pick a labelmaker from the same range.

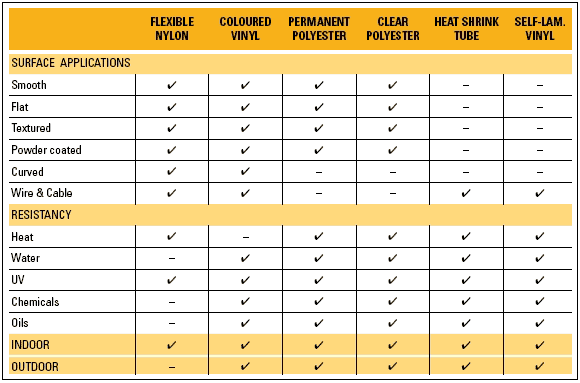

For tough surfaces, industrial settings and specialist tasks such as cable labelling you should really be looking at the Dymo Rhino range of labels, some of which are designed specifically for such highly curved surfaces, as well as dirty or textured surfaces. The Rhino labels all have more aggressive adhesive for extra sticking power, and a range of label materials (polyester, nylon, vinyl, heat shrink) for different surfaces/environments. See the table below for a guide on which type of label is best for your needs.

In addition to the Rhino range, the D1 (office range) labels do have a few specialist labels such as the Durable D1 labels which provide better adhesion and extra toughness, and the D1 Flexi Nylon tapes for curved surfaces.

So when choosing a labeller, first select the best type of label and then buy a label printer that is compatible with that range of labels. That way your labels should stay stuck!

(Also note that the labels have a shelf life of around 2 years, so if your tape has been sat around on the shelf for years, or has been kept in the wrong environment then that may affect the adhesive before you even try to stick it to anything)

Hi - i need to add some labels to some 3d printed parts, the underlying material will be PLA which doesn't make it easy to find a label that will stick.

Would any of the rhino labels work on PLA?

Thanks

Andy

They'll be the best bet from the Rhino range. I'd recommend either the Vinyl or Nylon. If you want to test without spending money on the printer, you could just buy a tape, pull some out and see if it sticks. If it is suitable then you can buy a printer.